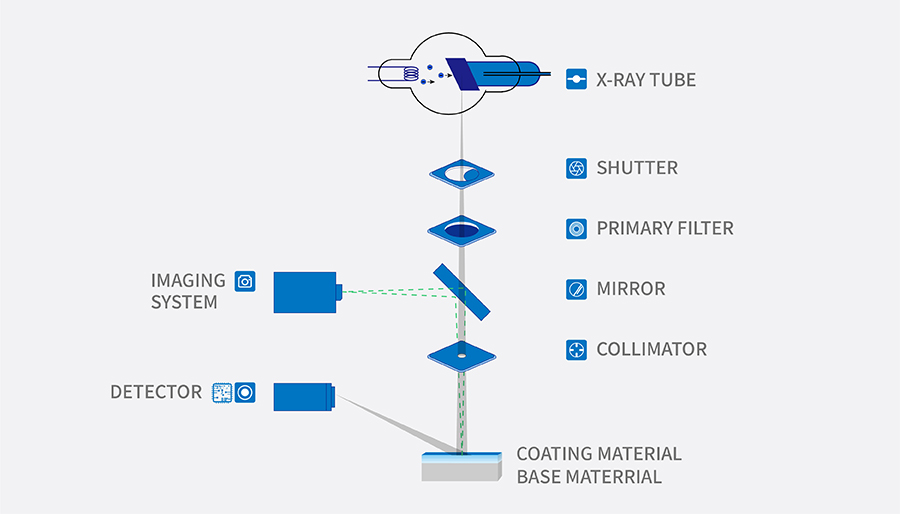

The content of quality inspection of different coating products varies depending on the part and coating, but the appearance, thickness, corrosion resistance and bonding force with the base metal of the coating must be checked for all coatings, and the thickness of the coating is the quality of the coating. Among them, the thickness of the coating is the most important guarantee factor for the quality of the plated parts. Aiming at the detection and screening problems in the process control of surface treatment, product quality inspection and other links in the ironware application, LANScientific provides you with an efficient and intelligent XRF analysis instrument – INSIGHT, INSIGHT coating analyzer is a up-bottom coating analyzer with high sensitivity, non-destructive, simple operation, high test accuracy, compact appearance, space saving, etc. It can not only be used for elemental analysis of samples with uneven, irregular, and even small shapes, but also for thickness measurement of coatings and coating systems.,It is widely used in quality control, incoming material inspection and production process control of various products to help customers reduce material costs and meet corresponding industrial standards.

Multi-collimator

One-touch measurement

Nondestructive testing

High-performance imported detector

High-precision manual X-Y platform

| The characteristics of | Top-down measurement structure, XYZ measurement platform, MUTI-FP multilayer algorithm |

| Scope of element | Na(11)—Fm(100) |

| Analysis of the layer number of | 5 layers (4 layers + substrate) each layer can analyze 10 elements, composition analysis can analyze up to 25 elements |

| X-ray tube | 50 W (50 kV, 1mA) micro-focused tungsten palladium ray tube (target material is optional) |

| The detector | Si-PIN large area detector |

| Collimator | φ0.5-φ5 is optional. Multi-standard is optional |

| The camera | High resolution CMOS color camera, 5 megapixels |

| magnification | 40x-160x |

| Manual sample XY platform | Moving range:100 x 150 mm |

| Programmable XY platform | (Optional) |

| Z-axis range of movement | 150 mm |

| Sample bin size | 520 x 480 x 170 mm(L x W x H) |

| Overall dimensions | 624 x 702 x 730 mm(L x W x H) |

| weight | 120KG |

| The power supply | AC 220V±5V 50Hz(The configuration varies slightly by region) |

| Rated power | 150W |